Introduction:

“Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH)” is the European Union’s mandatory registration, evaluation, licensing and safety implementation for all chemicals entering the EU market. The legal regulations established for monitoring came into effect on June 1, 2007, and are managed by the European Chemicals Agency.

For the latest information on REACH, please refer to: https://echa.europa.eu/home

- Introduction:

The Restriction of Hazardous Substances Directive 2002/95/EC (abbreviated as RoHS) is an environmental protection directive (but not a law) passed by the European Union in February 2003 and is scheduled to be implemented in July 2006. Effective from January 1st, it mainly focuses on product ingredients and engineering process standards in manufacturing.

For the latest information on RoHS , please refer to: https://environment.ec.europa.eu/topics/waste-and-recycling/rohs-directive_en

The US Environmental Protection Agency announced that the PIP (3:1) isopropylated triphenyl phosphate restriction regulations have been extended to October 31, 2024.

The U.S. Environmental Protection Agency announced final regulations in January 2021. The restrictions and management actions for five PBT substances were supposed to be implemented gradually starting from March last year. However, after the announcement of the regulations, domestic and foreign manufacturers have successively received complaints that they are difficult to implement, especially regarding the PIP (3:1) restriction that prohibits processing and commercial distribution immediately after March 8, 2021, and the period for which supply chain information should be retained. Express the difficulty of execution. Manufacturers stated that this deadline will affect many important consumer and industrial products, such as mobile phones, laptops and other electronic equipment, as well as other industrial or commercial equipment used in transportation, life sciences, and semiconductor manufacturing for a wide range of purposes.

Reference: https://www.chemexp.org.tw/content/topic/TopicDetail.aspx?tid=22&id=4589

The four UV absorbers UV-328, UV-320, UV-327 and UV-350 are all SVHC substances under REACH regulations. They are also included in the list of substances requiring authorization in Appendix 14 of REACH. The sunset date is November 27, 2023. .

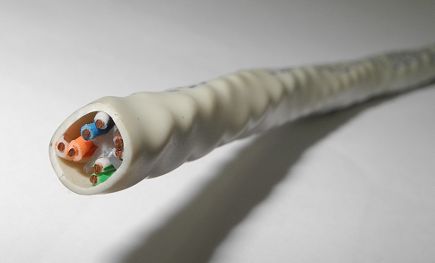

These four UV absorbers are all used in plastics, electrical appliances, optics and measuring equipment. Among them, UV-328 is the substance with the largest number of notifications to the SCIP database in these industries. It is mainly used in interior and exterior parts of vehicles, aircraft parts, and liquid crystals. Display (LCD) panels, various rubber products, cables, switches, plugs and sockets, IT and communication equipment, cameras and lenses, plastic films, sheets and labels, as well as high-performance polymers and additives for interior and exterior building materials.

| Substance Name | Chinese name | CAS No. | Possible uses |

| 2-benzotriazol-2-yl-4,6-di-tert-butylphenol UV-320 | 2-[2-Hydroxy-3′,5′-di-tert-butylphenyl]-benzotriazole | 3846-71-7 | UV stabilizer for plastics, PU and rubber, used in coating formulations |

| 2,4-Di-tert-butyl-6-(5-chlorobenzotriazol-2-yl) phenol UV-327 | 2,4-Di-tert-butyl-6-(5-chlorobenzotriazol-2-yl)phenol | 3864-99-1 | UV stabilizers for automobiles, industrial wood coatings, rubber, plastics, cosmetics |

| 2-(2H-benzotriazol-2-yl)-4,6-ditertpentylphenol UV-328 | 2-(2′-Hydroxy-3′,5′-di-tert-pentylphenyl)benzotriazole | 25973-55-1 | UV stabilizer for plastics, PU and rubber, used in coating formulations |

| 2-(2H-Benzotriazol-2-yl)-4-(tert-butyl)-6-(sec-butyl) phenol UV-350 | 2-(2H-benzotriazol-2-yl)-4-(tert-butyl)-6-(sec-butyl)phenol | 36437-37-3 | UV stabilizers for automobiles, industrial wood coatings, rubber, plastics, cosmetics |

Reference: https://www.intertek – twn.com/FrontEnd/newseventsview.aspx?lang=C&no=12198

|  |

| Before | After |

formula:

PVC

100

Plasticizer

40-60%

Stabilizer

4%

Sb2O3

2-4%

UC1251

20-40

Other

as needed

Introduce:

PVC’s fire resistance or self-extinguishing properties are inherently good.

However, since other materials (HDPE, TPE…) are often used in cable structures,Or have higher flame resistance requirements,It is necessary to add appropriate additives.Among them, inorganic flame retardants combined with Sb2O3 are most commonly used.In this way, a high flame retardant effect of rapid encrustation can be achieved.

Introduction:

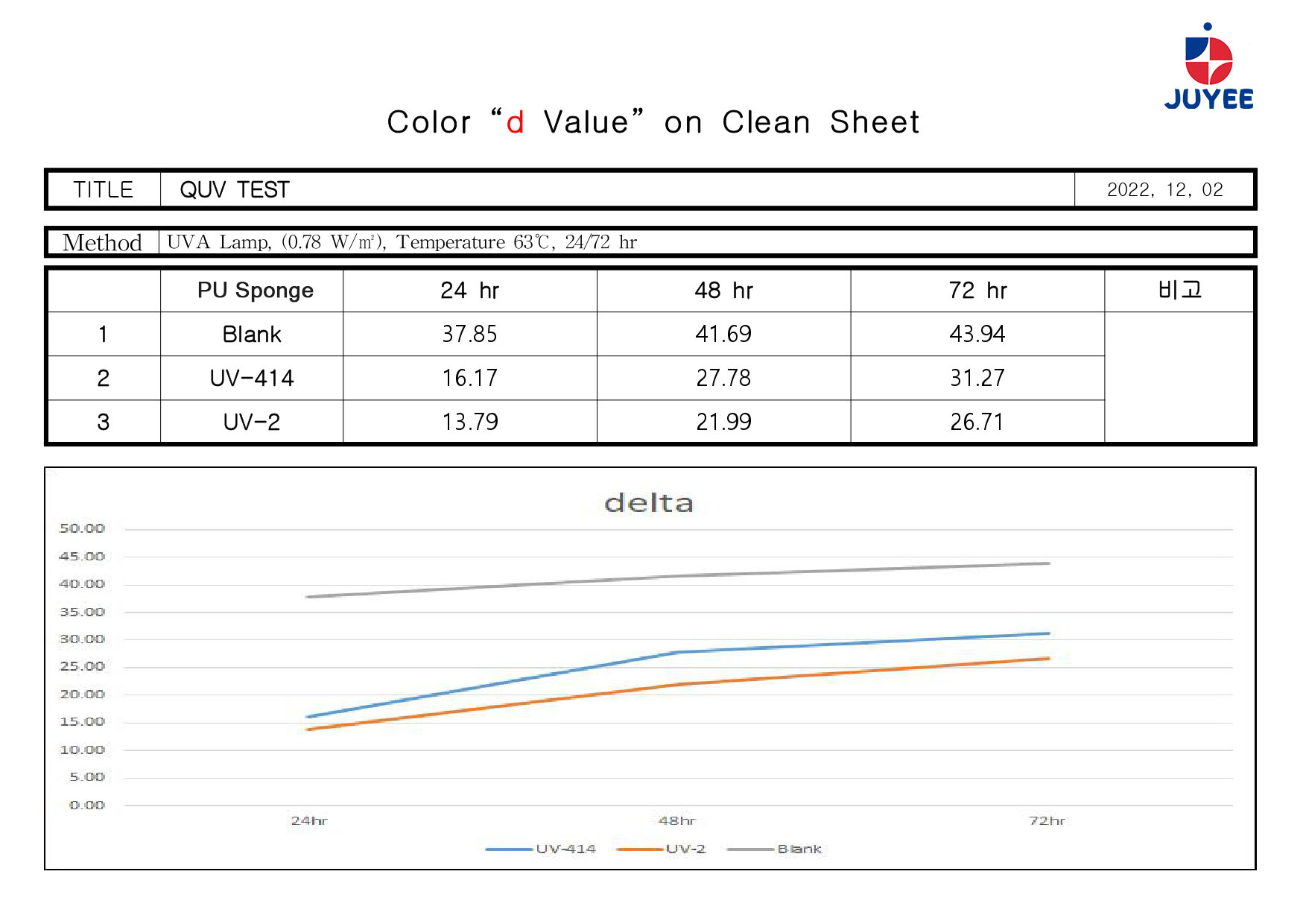

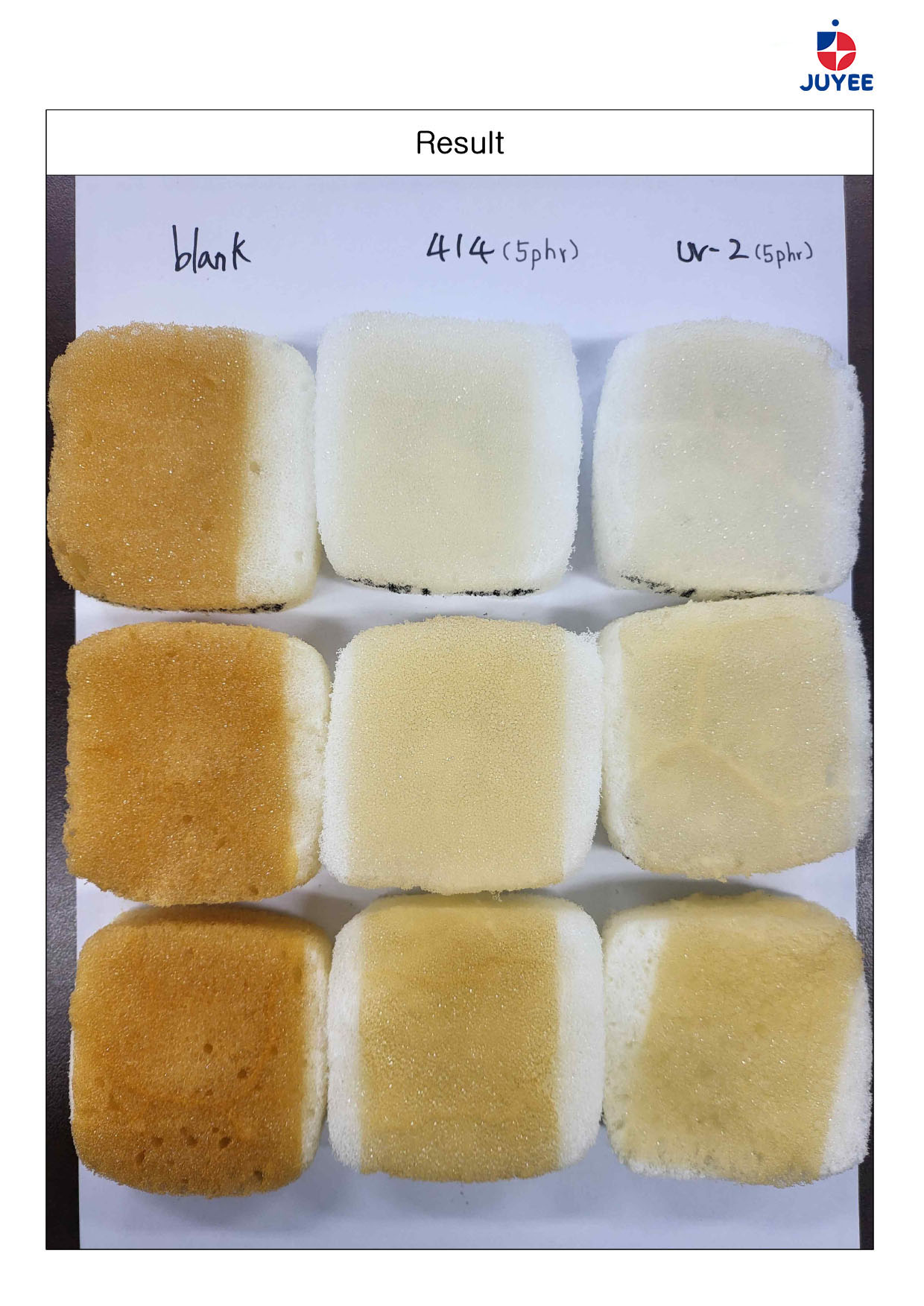

PU foam is very easy to yellow.

Anti-yellowing agent must be added

UV-2 is an effective and simple anti-yellowing agent for PU foam .